Service

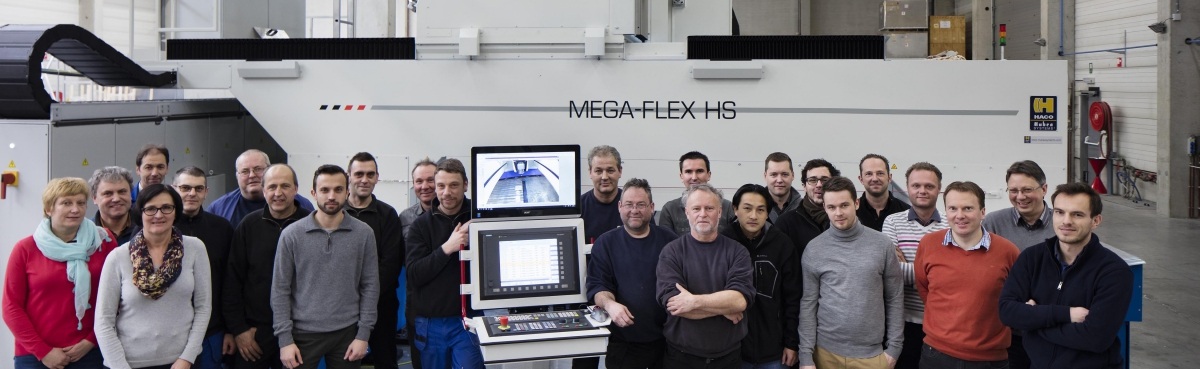

Your production machines are your moneymakers. Whatever happens with them, you need to know that you will get a fast response to every service request. That is precisely why our entire professional service organization operates from local branches.

That way, our qualified service engineers never have to break their promise of quick and efficient action. We have brought them as close to you as possible, through service departments in your own country.

Our investments in a local presence should also tell you how important service continuity over the long term is to us. Even if your equipment needs reengineering or retrofitting after more than twenty years of service, we are always where you need us.

About us

Mubea History

Mubea Systeme was acquired by the Haco Group S.A. in 1996, this completing its offering of multi-purpose metal working machines. Mubea Systeme combined the knowledge form the profile industry with the HACO metal & wood industry.

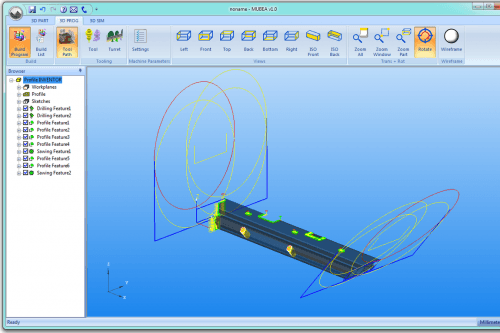

3D measuring

Mubea Systeme has developed a special measurement solution for industrial profiles. The secret of success? Measuring just before machining, not after. Plus, the 3D measuring and the machining are performed in the same programme – one flow, one process...

The right machine for each process

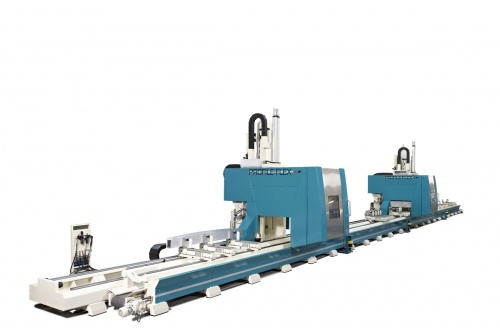

Mubea Systems offers a complete range of 5-axis CNC machining centres, specially designed for automatic tooling of exceptionally long aluminium profiles and panel profiles (e.g., aluminium profiles that are laid next to, and welded to, each other to construct a large floor for a train).

Mubea Systems = Machine + Software + Measuring + Clamping System in 1 solution

Mubea Systems is the only company in the world that has all 4 key-points for industrial cutting of aluminium profiles in-house (no external companies involved):

News

Mubea Systems: advanced solutions for the aviation industry

25 April 2017

Mubea Systems manufactures a complete range of 5-axis CNC machining centers: we offer machinery designed for automatic tooling of exceptionally long aluminum profiles and high speed cutting of solids in aluminum and new materials like titanium

2017: a year of growth for the HACO Group

19 January 2017

HACO keeps expanding and takes over Design Technologies International (DTI), offering smart solutions to today’s tough applications.

High Speed CNC Machining Center for Aviation customer

11 February 2016

Mubea Systems recently built a High Speed Machining Center for an important customer in the aviation industry. The MegaFlex High Speed will be used to machine Aircraft Structural Frames.

MIDAS: high precision extruded aluminium products for high-speed and metro trains

7 January 2016

MIDAS manufactures a wide variety of large-section and high-precision aluminium alloy extruded products which are primarily used in the body frames of high-speed passenger trains and metro trains. The Mubea Profile Machining Centers machine the profiles to high-precision products!

Sjoelund machines bended aluminium extrusions with Multi-Flex!

4 January 2016

Sjoelund, specialised in bending aluminium extrusions, has invested in a Mubea Multi-Flex profile machining center. After bending and heating the aluminium profile, the Multi-Flex measures and machines the bended profiles. From small standard extrusions to extrusions for windows and facades as well as the most complex profile cross-sections for use in buses and trains.